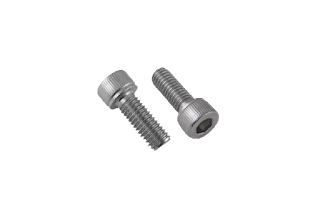

How Do Socket Head Cap Screw Manufacturers Ensure Precision and Durability in Their Products?

Socket head cap screws are essential components in various industries, known for their reliability and versatility. Manufacturers play a pivotal role in ensuring these screws meet high-quality standards. Let's delve into the process that helps socket head cap screw manufacturers achieve precision and durability.

Material Selection:

Socket head cap screw manufacturers begin by carefully selecting materials. Typically, they opt for alloys like stainless steel, alloy steel, or brass. The choice depends on the screw's intended application, as each material possesses distinct properties, such as corrosion resistance or high tensile strength.

Precision Machining:

Manufacturers employ state-of-the-art machining processes to craft socket head cap screws. Computer Numerical Control (CNC) machines meticulously shape each screw, ensuring uniformity and precision. This precision minimizes the risk of threading issues or misalignment during installation.

Heat Treatment:

To enhance the screws' mechanical properties, manufacturers subject them to heat treatment processes. This step involves heating the screws to specific temperatures and then rapidly cooling them. Heat treatment improves hardness, strength, and resistance to wear and fatigue.

Thread Rolling:

Achieving high-quality threads is paramount. Manufacturers often employ thread rolling techniques, which cold-form threads onto the screws. This method not only ensures accurate threading but also strengthens the screws, making them less susceptible to stripping or shearing.

Surface Finishing:

Socket head cap screws typically undergo surface finishing processes such as plating or coating. This enhances their corrosion resistance and appearance while maintaining their precise dimensions.

Quality Control:

Manufacturers use various inspection techniques, including visual checks, dimensional measurements, and torque testing, to guarantee that each screw meets the specified standards.

Certifications and Compliance:

Reputable manufacturers ensure their socket head cap screws comply with industry standards and regulations. They often obtain certifications like ISO 9001 or ASTM to demonstrate their commitment to quality.

In conclusion, socket head cap screw manufacturers employ a combination of material selection, precision machining, heat treatment, thread rolling, surface finishing, quality control, and compliance with standards to produce screws that are not only precise but also durable and reliable for a wide range of applications. These processes collectively ensure that these screws consistently perform their crucial roles in various industries.

Comments

Post a Comment